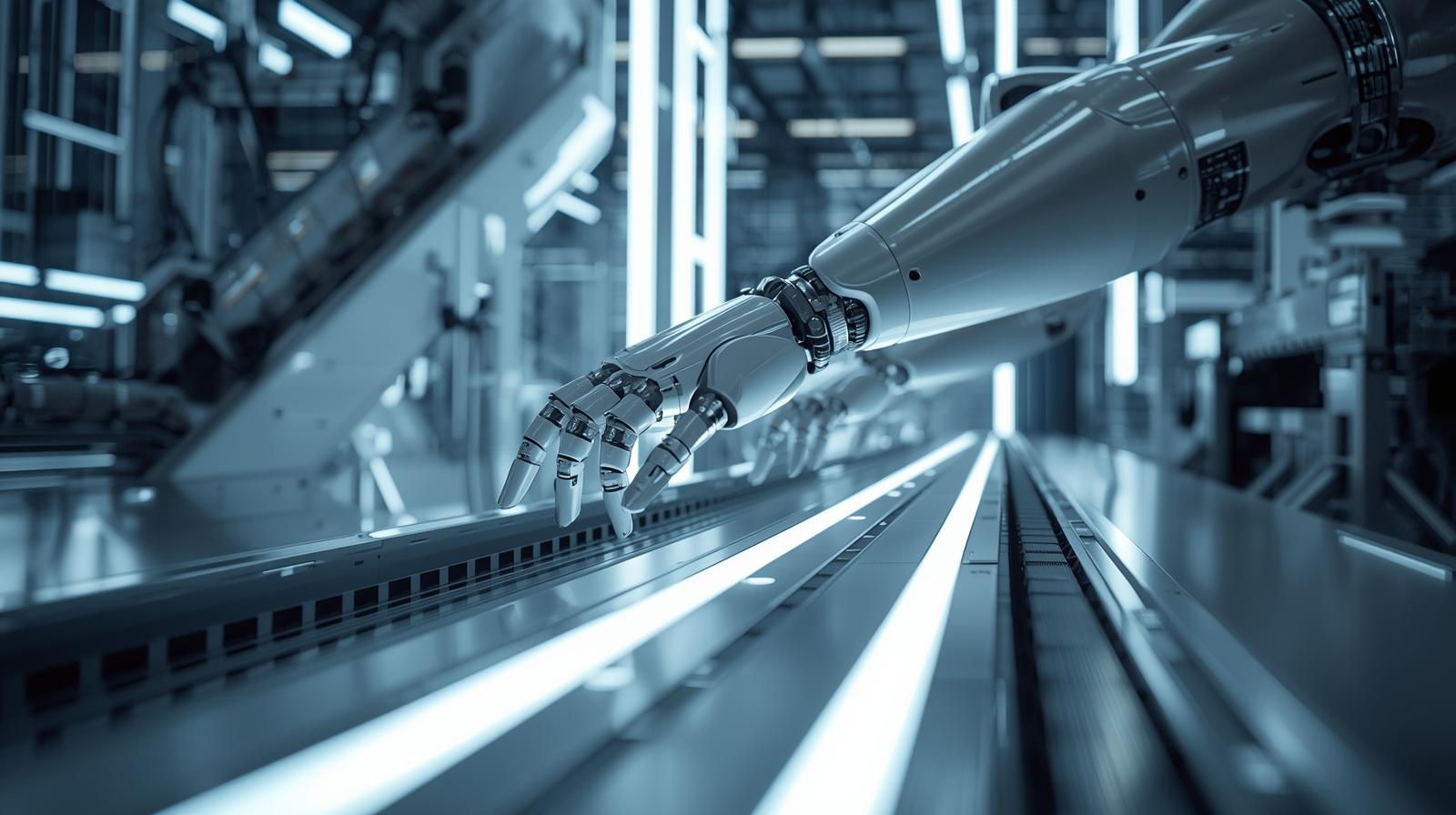

The energy sector has always powered progress. Every light switch, factory line, and digital service depends on it. Yet behind that reliability sits a complex web of infrastructure that must operate continuously, safely, and efficiently. As demand grows and systems age, the pressure to perform only increases. This is where robotics energy automation begins to change the story.

Robotics energy automation brings intelligent machines into environments that are dangerous, remote, or relentlessly repetitive. These machines inspect, repair, monitor, and optimize energy systems without fatigue. They work in extreme heat, deep water, high altitude, and hazardous conditions. As a result, productivity improves while risk declines.

Think of robotics energy automation as giving the energy sector a tireless workforce that never loses focus. Human expertise remains essential. However, robots extend reach, precision, and consistency in ways people alone cannot.

Why productivity is critical in modern energy systems

Energy systems operate under constant pressure. Demand fluctuates daily. Infrastructure ages. Environmental standards tighten. Downtime costs millions.

Traditional productivity gains relied on larger equipment or more labor. Both approaches now face limits. Costs rise. Safety risks grow. Efficiency plateaus.

Robotics energy automation offers a different path. Instead of scaling effort, it scales intelligence. Tasks become smarter rather than heavier. Systems adapt in real time. Productivity becomes sustainable.

Understanding robotics energy automation

Robotics energy automation refers to the use of autonomous or semi-autonomous robotic systems guided by software, sensors, and artificial intelligence to perform energy-related tasks.

These robots inspect pipelines, climb wind turbines, clean solar panels, monitor power lines, and service offshore platforms. Sensors collect data. Algorithms guide movement and decision-making.

Unlike traditional automation, robotics operate in unstructured environments. They adjust to terrain, weather, and unexpected conditions. This flexibility makes them ideal for energy applications.

Robotics automation in power generation facilities

Power plants require constant monitoring and maintenance. Heat, pressure, and mechanical stress create harsh conditions.

Robotic systems inspect boilers, turbines, and cooling systems while plants remain operational. Cameras and sensors detect cracks, corrosion, and leaks early.

As a result, shutdowns become planned rather than reactive. Maintenance becomes predictive. Productivity increases because assets run longer and more reliably.

Robotics energy automation turns inspection into a continuous process rather than a periodic disruption.

Improving safety through robotics energy automation

Safety remains a top priority in energy operations. Many tasks expose workers to extreme risk.

Robots now enter confined spaces, high-voltage zones, and contaminated areas. They perform inspections without endangering lives.

By removing humans from hazardous environments, incident rates drop. Training costs decline. Insurance risks shrink.

Safety improvements directly support productivity by preventing delays caused by accidents.

Automation-driven productivity in renewable energy

Renewable energy systems spread across vast areas. Wind farms stretch offshore. Solar fields span miles.

Manual inspection becomes costly and slow. Robotics energy automation changes that.

Drones inspect wind turbine blades mid-operation. Ground robots clean solar panels efficiently. Autonomous vehicles monitor battery storage sites.

Maintenance becomes faster and more accurate. Energy output remains optimized.

Renewables scale more easily with robotic support.

Robotics in wind energy maintenance

Wind turbines operate under constant stress. Blade damage reduces efficiency quickly.

Robotic climbers and drones inspect blades regularly. They detect micro-cracks invisible from the ground.

Some robots perform minor repairs on-site. Downtime decreases. Output stabilizes.

Robotics energy automation keeps turbines productive without costly shutdowns.

Solar energy optimization through robotics

Dust and debris reduce solar panel efficiency significantly. Cleaning manually is labor-intensive.

Robotic cleaners operate regularly without water waste. Sensors guide movement precisely.

Panels maintain peak efficiency. Energy yield increases.

Automation transforms maintenance from a burden into a routine advantage.

Robotics automation in oil and gas operations

Oil and gas infrastructure often sits in remote or hostile environments. Offshore platforms, deep wells, and pipelines require constant vigilance.

Robotic systems inspect pipelines internally and externally. Autonomous underwater vehicles survey subsea assets.

Leaks are detected early. Repairs occur faster. Environmental damage is minimized.

Robotics energy automation reduces risk while improving operational continuity.

Pipeline inspection and monitoring

Pipelines stretch for thousands of miles. Manual inspection is slow and incomplete.

Robotic crawlers and smart pigs travel inside pipelines. They scan for corrosion, cracks, and blockages.

Data flows in real time. Maintenance targets precise locations.

Productivity improves because inspection becomes thorough and continuous.

Offshore energy automation

Offshore energy operations face weather, depth, and distance challenges.

Robotic arms, underwater drones, and autonomous platforms perform inspections and repairs without human exposure.

Operations continue during rough conditions. Costs decline.

Robotics energy automation extends human capability far beyond physical limits.

Grid inspection and maintenance automation

Power grids span vast territories. Line failures cause widespread outages.

Robotic systems inspect transmission lines using drones and climbing robots. Sensors detect wear and vegetation interference.

Maintenance crews receive targeted instructions. Response time improves.

Grid reliability increases while labor strain decreases.

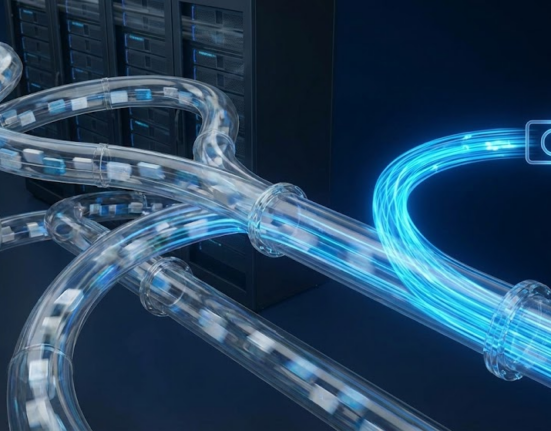

Predictive maintenance powered by robotics

Robots collect detailed data continuously. Vibration, temperature, and visual signals reveal asset health.

AI analyzes patterns. Failures are predicted before they occur.

Maintenance schedules shift from reactive to predictive.

Robotics energy automation transforms maintenance into a productivity driver.

Reducing downtime across energy assets

Downtime costs energy companies heavily. Every idle asset reduces revenue.

Robotic inspections reduce unplanned outages. Repairs occur faster and with precision.

Assets stay online longer. Output increases.

Productivity improves through availability rather than speed alone.

Data-driven decision-making in energy automation

Robots generate vast data streams. Every inspection adds insight.

Analytics reveal inefficiencies, degradation trends, and optimization opportunities.

Managers make informed decisions. Investments target real needs.

Robotics energy automation turns data into strategic advantage.

Energy storage systems and robotics

Battery storage systems grow rapidly. Monitoring safety and performance matters.

Robots inspect battery arrays for heat anomalies and damage. Automated systems respond instantly.

Storage reliability improves. Safety risks decline.

Productivity rises as storage assets operate optimally.

Reducing operational costs through automation

Labor costs, downtime, and safety incidents drive expenses.

Robotics energy automation reduces each factor. Inspections become cheaper. Repairs become targeted.

Long-term savings outweigh initial investment.

Cost efficiency strengthens competitiveness.

Scalability and flexibility of robotic systems

Energy systems evolve. New sites appear. Old assets retire.

Robotic systems scale easily. Software updates adapt behavior. Hardware redeploys across sites.

Flexibility supports growth without massive retraining.

Productivity scales smoothly.

Workforce transformation and collaboration

Automation reshapes roles rather than eliminating them.

Workers supervise robots, analyze data, and plan strategy. Dangerous tasks decline.

Job quality improves. Skills shift toward technology and oversight.

Robotics energy automation supports a safer, more skilled workforce.

Training and adoption challenges

Adoption requires training and trust. Workers must understand systems.

Gradual deployment helps. Pilots demonstrate value. Feedback refines processes.

Challenges fade as familiarity grows.

Successful adoption depends on collaboration.

Regulatory and compliance benefits

Energy regulation demands documentation and inspection.

Robotic systems record data consistently. Audit trails become automatic.

Compliance improves without extra workload.

Robotics energy automation supports regulatory confidence.

Environmental benefits of automation

Robotics reduce environmental risk. Early detection prevents spills. Efficient operations reduce waste.

Renewable systems operate more efficiently. Emissions decline.

Productivity aligns with sustainability goals.

Cybersecurity considerations in robotic energy systems

Connected robots introduce cyber risk. Security must be strong.

Access controls, encryption, and monitoring protect systems.

Secure design ensures automation does not create new vulnerabilities.

Trust underpins productivity.

Global adoption trends in robotics energy automation

Energy companies worldwide adopt robotics at different speeds.

Harsh environments drive early adoption. Cost pressures accelerate interest.

Shared innovation spreads best practices.

Global productivity improves collectively.

Future innovations in energy robotics

Robotics will become more autonomous. Swarms may inspect assets collaboratively.

AI vision will improve accuracy. Energy-efficient designs will extend operation.

Robotics energy automation will grow smarter and more independent.

Resilience and disaster response

Extreme weather threatens energy systems.

Robots assess damage quickly after storms. Repairs begin sooner.

Resilience improves. Recovery accelerates.

Automation strengthens response capability.

Integration with smart energy systems

Robotics integrate with smart grids and IoT platforms.

Data flows seamlessly. Systems coordinate automatically.

Energy networks become adaptive and intelligent.

Productivity reaches new levels.

Economic impact of automation-driven productivity

Automation improves margins and stability.

Investments attract funding. Energy prices stabilize.

Communities benefit from reliable supply.

Robotics energy automation supports economic resilience.

Ethical deployment and responsibility

Automation must respect safety and employment considerations.

Transparent deployment builds trust. Safety standards guide use.

Responsible adoption ensures shared benefits.

Ethics and productivity coexist.

Conclusion

Robotics energy automation is unlocking a new era of productivity across the energy sector. By combining intelligent machines with human expertise, organizations achieve safer operations, reduced downtime, and smarter decision-making.

Automation does not replace the human role. It amplifies it. Dangerous tasks diminish. Insight grows. Systems become resilient and adaptive.

As energy demands rise and complexity increases, robotics energy automation offers a path forward that is efficient, responsible, and sustainable. The future of energy is not just powered. It is intelligently automated.

FAQ

1. What is robotics energy automation?

It is the use of robotic systems and automation to perform tasks across energy production, maintenance, and monitoring.

2. How does robotics automation improve energy productivity?

It reduces downtime, improves safety, and enables predictive maintenance.

3. Are robots used in renewable energy systems?

Yes, they inspect, clean, and maintain wind, solar, and storage assets.

4. Does automation reduce energy sector jobs?

It mainly shifts roles toward supervision, analysis, and higher-skill tasks.

5. Is robotics energy automation safe?

When designed securely, it significantly improves safety and operational reliability.