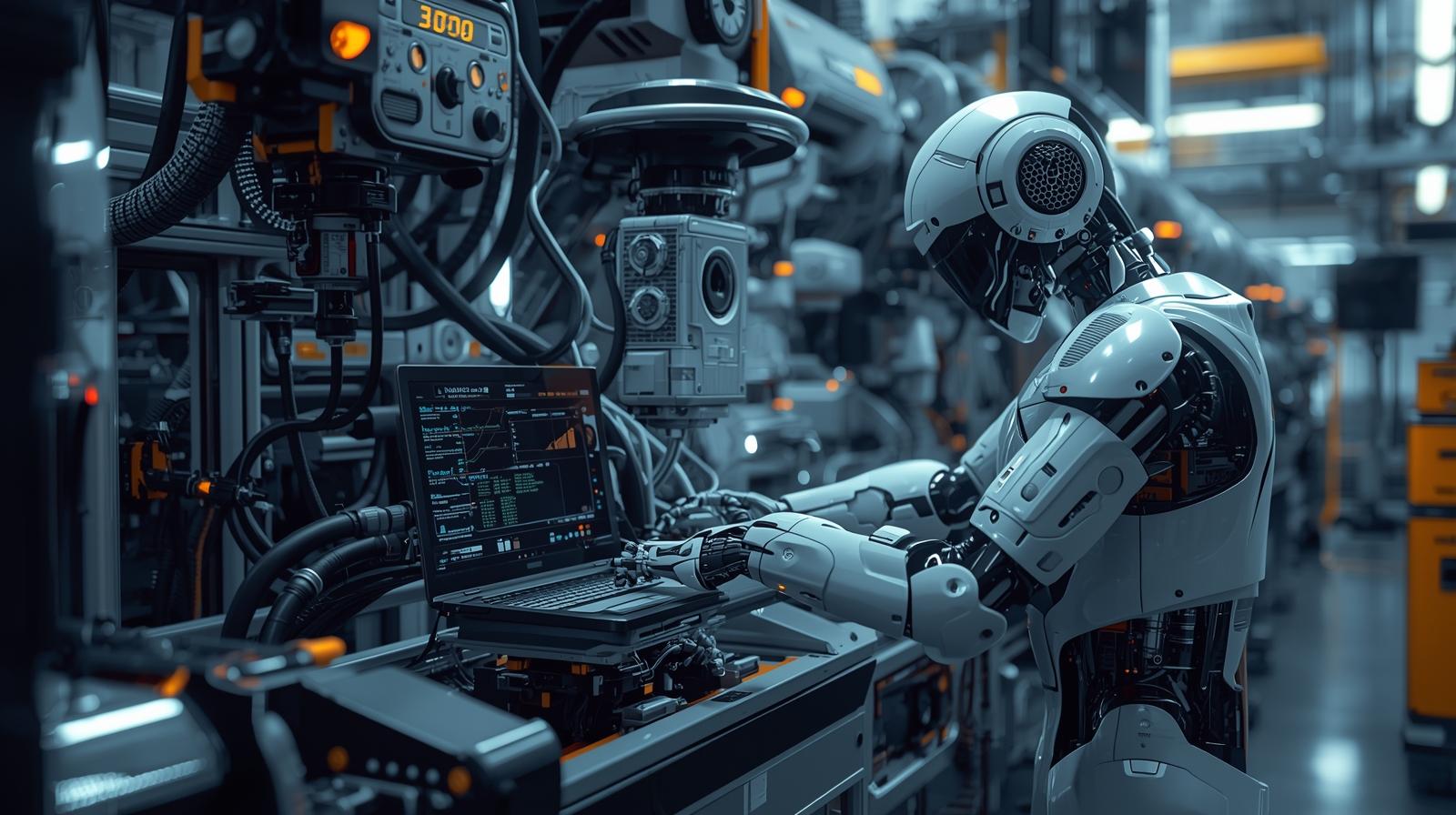

Robotics predictive maintenance is reshaping how organizations care for critical equipment. Instead of waiting for machines to fail or relying on rigid schedules, teams now act based on real conditions. That shift feels like upgrading from a paper map to live navigation. You see problems before you reach them.

Traditional maintenance models were built for a slower world. Machines were checked after breakdowns or serviced on fixed intervals. While that approach felt safe, it wasted resources. Healthy parts were replaced too early. Hidden issues went unnoticed.

Robotics changes that dynamic.

By pairing intelligent machines with data-driven maintenance strategies, organizations gain foresight. Equipment health becomes visible. Decisions become proactive. Downtime becomes predictable rather than chaotic.

This article explains how robotic automation unlocks predictive maintenance, why it matters, and how industries apply it successfully.

Why Predictive Maintenance Needs Robotic Support

Predictive maintenance depends on continuous observation. Sensors generate data, yet someone or something must collect and interpret it consistently.

Humans cannot monitor everything. Fatigue sets in. Coverage gaps appear. Dangerous environments limit access.

Robots fill those gaps.

Autonomous machines inspect assets around the clock. They move through facilities without rest. They enter confined or hazardous spaces safely.

Robotics predictive maintenance benefits from this persistence. Instead of snapshots, teams receive a steady stream of insight.

As a result, issues surface early rather than during emergencies.

How Robotics Enable Condition-Based Maintenance

Robots act as mobile sensing platforms. They observe, measure, and record.

Some inspect visual wear using cameras. Others listen for abnormal acoustics. Many capture vibration, temperature, or pressure data.

Because robots follow repeatable paths, measurements remain consistent. That consistency improves trend analysis.

Robotics predictive maintenance thrives on reliable input. When data quality improves, predictions improve too.

Small anomalies become visible long before failure.

From Scheduled Tasks to Intelligent Interventions

Scheduled maintenance assumes machines degrade uniformly. Reality disagrees.

Usage varies. Environments differ. Loads fluctuate.

Automation-driven maintenance adapts to these conditions. Robots collect real-time signals. Analytics evaluate health continuously.

Maintenance occurs when needed, not when the calendar says so.

Think of it like monitoring heart rate instead of scheduling doctor visits blindly. The signal matters more than the date.

Robotic Inspection in High-Risk Environments

Many assets operate where humans cannot linger safely.

Extreme heat, high voltage, toxic substances, and confined spaces all limit access.

Robots thrive in these conditions.

Drones inspect elevated structures. Crawlers navigate pipelines. Wheeled robots patrol industrial floors.

Robotics predictive maintenance expands visibility into areas once checked rarely or not at all.

Better coverage leads to fewer surprises.

Data Consistency as a Competitive Advantage

Human inspections vary. Experience, fatigue, and judgment influence results.

Robots deliver repeatability.

This consistency strengthens analytics.

Robotics predictive maintenance depends on trends. Reliable input reveals subtle change. Inconsistent data hides it.

Consistency turns observation into insight.

Integrating Robotics with Existing Maintenance Systems

Robots do not replace maintenance platforms. They feed them.

Collected data flows into asset management systems. Insights integrate with work order tools.

Technicians receive recommendations rather than raw numbers.

Robotics predictive maintenance works best when integrated smoothly. Robots become another sensor layer, not a separate silo.

Familiar workflows remain intact while intelligence increases.

Predictive Analytics and Machine Learning

Data alone does not create foresight.

Machine learning models analyze patterns across time. They correlate sensor changes with historical failures.

Robots provide high-quality input. Models convert it into predictions.

This partnership drives value.

Robotics predictive maintenance relies on analytics to answer one question. What will fail next, and when?

When models improve, confidence grows.

Reducing Unplanned Downtime

Unexpected downtime disrupts operations fast.

Production stops. Schedules collapse. Costs rise.

Early detection changes the story.

Robots spot anomalies before alarms trigger. Maintenance teams plan repairs during low-impact windows.

Robotics predictive maintenance transforms chaos into control.

Downtime becomes manageable instead of catastrophic.

Extending Equipment Lifespan

Assets last longer when cared for precisely.

Over-maintenance wears components unnecessarily. Under-maintenance accelerates failure.

Robotic monitoring finds balance.

Wear trends guide intervention. Components are replaced when needed, not prematurely.

Robotics predictive maintenance protects capital investment. Equipment delivers full value over time.

That benefit compounds year after year.

Improving Safety Through Automation

Maintenance work carries risk.

Heavy machinery, confined spaces, and hazardous materials increase danger.

Robots reduce exposure.

Robotics predictive maintenance improves safety by design.

Fewer incidents follow.

Scaling Predictive Maintenance Across Sites

Large organizations operate multiple facilities. Consistency becomes difficult.

Robots scale easily.

Standardized inspection routines run everywhere. Data aggregates centrally. Performance compares across locations.

Robotics predictive maintenance supports enterprise-wide visibility without increasing headcount.

Scale becomes an advantage rather than a burden.

Cost Efficiency and Return on Investment

Robotic automation requires upfront investment. However, returns appear quickly.

Reduced downtime saves revenue. Fewer emergency repairs cut costs. Extended asset life delays replacement.

Robotics predictive maintenance shifts spending from reaction to optimization.

Over time, savings outweigh initial expense.

Addressing Workforce Concerns

Automation often raises concern.

In practice, roles evolve.

Robots handle repetitive inspection. Humans focus on diagnosis, planning, and improvement.

Robotics predictive maintenance supports technicians rather than replacing them.

When positioned clearly, adoption improves morale.

Managing Change During Adoption

Technology alone does not ensure success.

Clear communication matters. Training builds confidence. Pilots demonstrate value.

Start small. Expand gradually.

Robotics predictive maintenance succeeds when people trust the system.

Trust grows through results.

Cybersecurity and Data Integrity

Connected robots introduce digital risk.

Networks must be secured. Data must be protected. Access must be controlled.

Encryption and monitoring reduce exposure.

Robotics predictive maintenance depends on trustworthy data. Security preserves that trust.

Industry Applications of Robotic Maintenance

Manufacturing uses robots to inspect motors and conveyors. Energy companies monitor turbines and pipelines. Logistics centers track sorting systems.

Each industry adapts the approach to context.

Robotics predictive maintenance proves versatile across sectors.

Where machines operate, insight helps.

Overcoming Common Implementation Challenges

Challenges appear during rollout.

Integration complexity, data overload, and cultural resistance slow progress.

Clear objectives help. Strong partners help. Iteration helps.

Robotics predictive maintenance improves with learning.

Early friction fades.

Measuring Maintenance Success

Metrics guide improvement.

Downtime reduction. Cost savings. Asset availability. Safety incidents.

Compare before and after.

Robotics predictive maintenance delivers value when measured consistently.

Data validates decisions.

Future Trends in Robotic Maintenance

Robots grow more autonomous. Sensors grow smaller. Analytics grow faster.

Edge computing reduces latency. Collaborative robots share tasks.

Robotics predictive maintenance will become increasingly adaptive.

Early adopters gain resilience.

Recommended Image Alt Text for This Topic

Alt text example: robotic inspection system monitoring industrial equipment

Alt text example: autonomous robot performing predictive maintenance check

Alt text example: industrial robot collecting vibration data for maintenance analysis

Conclusion

Robotics predictive maintenance transforms maintenance from a reactive cost into a strategic capability. By combining robotic inspection, intelligent analytics, and automated workflows, organizations gain foresight instead of surprises.

Assets last longer. Downtime shrinks. Safety improves. Teams focus on value rather than emergencies.

This approach does not replace people. It empowers them.

When robotics and predictive maintenance work together, operations move from fragile to future-ready.

FAQ

1. What is robotics predictive maintenance?

It is the use of robots and data analytics to detect equipment issues before failure occurs.

2. How do robots support predictive maintenance?

They inspect assets continuously, collect consistent data, and access hard-to-reach areas.

3. Is robotic maintenance automation expensive?

Initial costs exist, but reduced downtime and longer asset life often deliver strong ROI.

4. Can robotic maintenance work with older equipment?

Yes, most solutions integrate with existing machines and monitoring systems.

5. Does robotic automation replace maintenance staff?

No, it shifts staff toward higher-value analysis and planning tasks.