Productivity has always followed tools. From the wheel to the steam engine, progress accelerates when thinking meets execution. Today, that partnership is taking a new form. Artificial intelligence provides the brain. Robotics delivers the hands. Together, they form a powerful system that is redefining how work gets done.

AI robotics productivity is not a distant concept. It is already present in factories, hospitals, offices, and homes. While AI analyzes, predicts, and decides, robots move, lift, assemble, and interact. Separately, each technology adds value. Combined, they multiply impact.

Imagine a chess grandmaster paired with a tireless athlete. Strategy meets endurance. That is the essence of this duo. As a result, productivity no longer depends solely on human speed or strength. Instead, it thrives on collaboration between intelligent systems and physical automation.

Why AI and robotics belong together

AI excels at processing data. It recognizes patterns, learns from outcomes, and adapts quickly. Robotics, on the other hand, excels at precision and repetition. When these strengths merge, systems become both smart and capable.

Without AI, robots follow rigid scripts. They repeat tasks but cannot adjust easily. Without robots, AI remains abstract, trapped in digital space. However, when AI guides robotic actions, machines respond dynamically to real-world conditions.

This synergy explains why AI robotics productivity has grown so rapidly. Sensors feed data to AI models. Decisions are made in milliseconds. Robots act immediately. Feedback loops close fast. Consequently, operations improve continuously rather than incrementally.

The productivity problem modern businesses face

Many organizations struggle with the same issues. Labor shortages persist. Costs rise steadily. Errors creep in when workloads increase. At the same time, customers expect speed and personalization.

Traditional automation helped, but it reached limits. Fixed machines could not adapt. Software alone could not touch physical processes. AI and robotics together break that ceiling.

By combining intelligence with movement, businesses unlock new efficiency. Tasks that once required teams now require systems. Yet humans remain essential. They supervise, design, and innovate while machines handle execution.

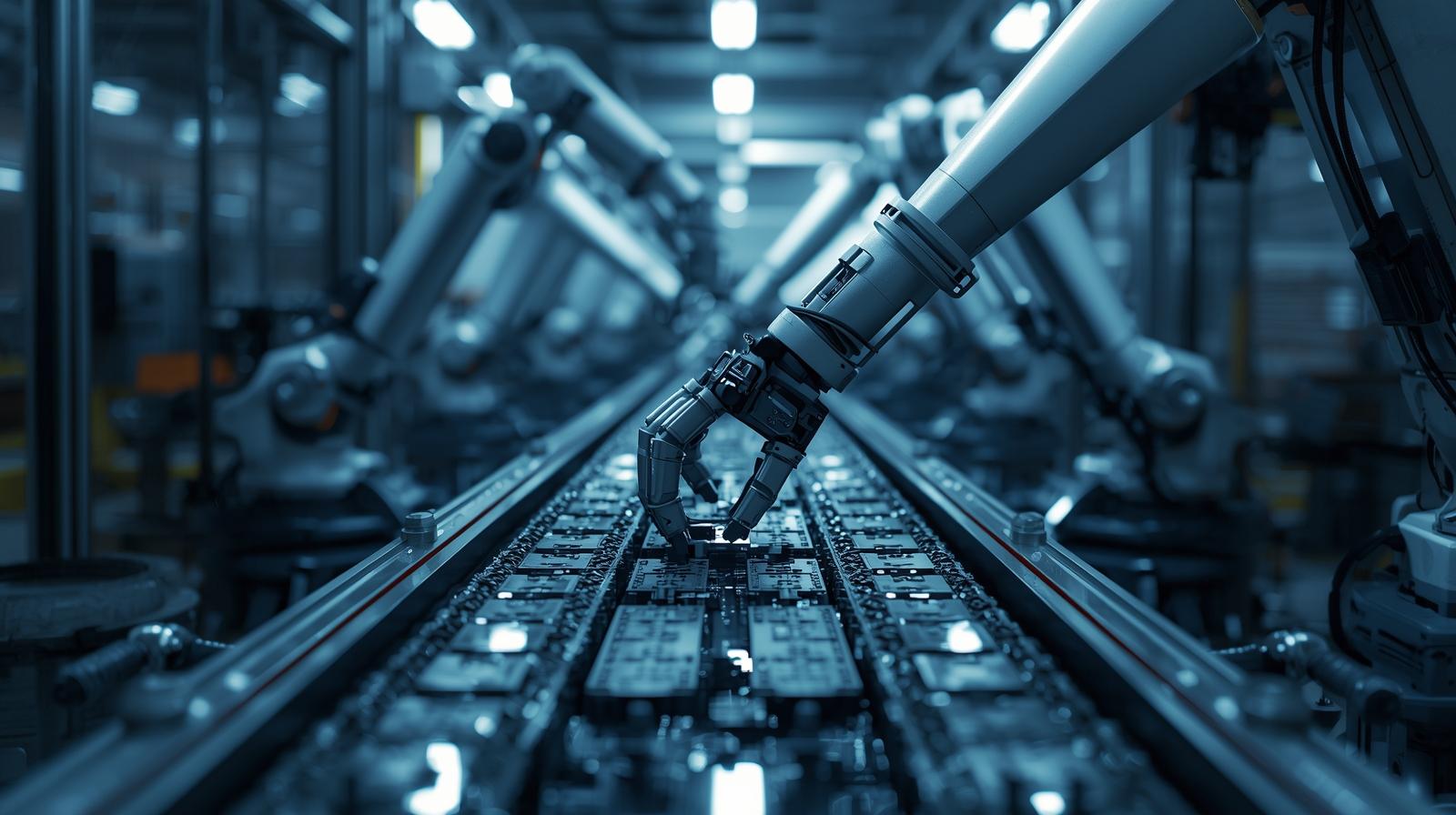

AI robotics productivity in manufacturing

Manufacturing provides the clearest example. Smart factories now use AI-driven robots to assemble products, inspect quality, and manage inventory. These robots see through cameras, feel through sensors, and learn from outcomes.

For instance, AI detects defects by analyzing images faster than any human inspector. Robots then remove faulty items instantly. Downtime shrinks. Waste drops. Output improves.

Moreover, collaborative robots, known as cobots, work safely beside people. They adjust speed and force automatically. As a result, productivity increases without sacrificing safety.

Smarter logistics and supply chains

Supply chains resemble living organisms. They respond to demand, disruptions, and delays. AI robotics productivity transforms these systems from reactive to proactive.

In warehouses, AI directs robots to pick, pack, and sort goods efficiently. Routes change dynamically. Bottlenecks are avoided. Inventory levels stay accurate.

During disruptions, AI models predict shortages early. Robots help reroute goods or accelerate fulfillment. Therefore, businesses remain resilient even under pressure.

Healthcare efficiency through intelligent automation

Healthcare demands precision, speed, and care. AI and robotics support all three. Surgical robots guided by AI assist doctors with delicate procedures. Accuracy improves. Recovery times shorten.

In hospitals, robots deliver supplies, disinfect rooms, and transport samples. AI schedules these tasks intelligently. Nurses spend more time with patients. Burnout decreases.

Diagnostic AI analyzes scans rapidly. Robotic systems then position patients or equipment correctly. Together, they reduce delays and improve outcomes.

Office productivity and service automation

AI robotics productivity is not limited to physical labor. Offices benefit too. Service robots greet visitors, guide customers, and manage reception tasks. AI chatbots handle inquiries while robots provide physical assistance.

In large facilities, robots equipped with AI perform security patrols. They recognize anomalies and alert staff. Consistency improves. Human teams focus on higher-value work.

Even remote operations benefit. AI monitors systems while robots execute maintenance tasks on-site. Distance becomes irrelevant.

Human-robot collaboration, not replacement

Fear often follows automation. However, AI robotics productivity is about augmentation, not elimination. Machines handle tasks that are dangerous, repetitive, or exhausting. Humans handle creativity, judgment, and empathy.

Consider construction. Robots lift heavy materials guided by AI. Workers supervise and adjust plans. Injuries decrease. Projects finish faster.

Similarly, in agriculture, AI-powered robots plant, monitor, and harvest crops. Farmers make strategic decisions. Productivity rises without losing human insight.

Learning systems that improve over time

One unique advantage of AI-guided robots is learning. Every task generates data. AI analyzes outcomes. Performance improves continuously.

If a robot slips slightly during assembly, AI adjusts grip strength. If a delivery route slows, AI recalculates. Over time, systems become more efficient without manual reprogramming.

This adaptability explains why AI robotics productivity scales so well. Improvements compound. Small gains accumulate into major advantages.

Energy efficiency and sustainability gains

Productivity is not just speed. It includes resource use. AI-driven robots optimize energy consumption. They operate only when needed. Idle time decreases.

In factories, AI schedules robotic tasks to minimize peak energy loads. In agriculture, robots apply water or fertilizer precisely. Waste declines.

Sustainable productivity becomes achievable. Businesses reduce costs while meeting environmental goals.

Data-driven decision making in real time

AI thrives on data. Robots generate it constantly. Sensors track movement, force, temperature, and timing. AI analyzes this information instantly.

Managers receive insights in real time. Decisions become proactive rather than reactive. Adjustments happen before problems escalate.

Because of this, AI robotics productivity improves not just execution but strategy. Leaders see operations clearly. Planning becomes smarter.

Challenges that must be managed

Despite benefits, challenges exist. Integration complexity remains high. Systems require investment and expertise. Data security matters greatly.

Workforce adaptation also matters. Employees need training. Trust must be built. Transparent communication helps ease transitions.

However, these challenges are manageable. With thoughtful planning, the benefits outweigh the obstacles significantly.

Industries accelerating fastest with AI robotics productivity

Certain sectors lead adoption. Manufacturing, logistics, healthcare, agriculture, and retail show rapid growth. However, others follow quickly.

Construction adopts autonomous equipment. Energy uses inspection drones. Hospitality explores service robots. Education experiments with robotic labs.

Each industry adapts the duo differently. Yet the productivity gains remain consistent.

The role of AI in robotic decision-making

AI acts as the decision engine. It prioritizes tasks, resolves conflicts, and adapts behavior. Without AI, robots remain static tools.

Machine learning allows robots to recognize objects, understand environments, and predict outcomes. Deep learning improves vision and speech.

As AI evolves, robots become more autonomous. However, human oversight remains essential for ethics and accountability.

Small businesses and accessibility

Once, robotics belonged only to large corporations. Today, costs fall steadily. Cloud AI and modular robots lower barriers.

Small businesses adopt AI robotics productivity through leasing, automation-as-a-service, and scalable platforms. Flexibility increases.

This democratization levels the playing field. Innovation spreads faster.

Global competitiveness and economic impact

Nations investing in AI and robotics gain productivity advantages. Output increases without proportional labor growth. Economies strengthen.

However, balance matters. Education and reskilling ensure inclusive growth. When workers evolve alongside technology, societies benefit.

AI robotics productivity becomes a national asset, not just a corporate tool.

Ethical and regulatory considerations

With power comes responsibility. AI-driven robots must operate safely and fairly. Transparency matters. Accountability frameworks help guide use.

Regulations evolve to address liability, privacy, and safety. Ethical design ensures trust remains intact.

When managed well, innovation and responsibility coexist.

The future of work shaped by intelligent machines

The workplace of tomorrow blends humans and machines seamlessly. AI handles analysis. Robots handle execution. People focus on purpose.

Productivity becomes smarter, not harder. Time frees up. Creativity flourishes.

This future is not science fiction. It unfolds now.

Conclusion

AI robotics productivity represents a turning point in how work is done. Intelligence without action limits impact. Action without intelligence limits growth. Together, AI and robotics create systems that think, adapt, and perform.

By embracing this partnership, organizations unlock efficiency, resilience, and sustainability. Humans remain central, guiding strategy and values. Machines amplify capability.

The perfect duo is not about replacing people. It is about empowering progress.

FAQ

1. What is AI robotics productivity?

It refers to productivity gains achieved by combining artificial intelligence with robotic automation.

2. How do AI and robotics improve efficiency together?

AI provides decision-making while robots execute tasks, creating adaptive and fast workflows.

3. Are jobs lost due to AI robotics productivity?

Some roles change, but many new roles emerge focused on supervision, design, and analysis.

4. Which industries benefit most from AI and robotics?

Manufacturing, healthcare, logistics, agriculture, and retail see major productivity improvements.

5. Can small businesses use AI-driven robots?

Yes, modern platforms and flexible models make adoption increasingly accessible.