Machine learning in manufacturing isn’t just a buzzword—it’s a revolution reshaping how products are designed, made, and delivered. Across the world, factories are moving from reactive operations to predictive, intelligent systems that learn and improve over time. It’s a shift that’s not only increasing efficiency but redefining the future of production.

Let’s explore how machine learning is transforming the manufacturing landscape—from predictive maintenance and quality control to supply chain optimization and beyond.

The Rise of Machine Learning in Modern Manufacturing

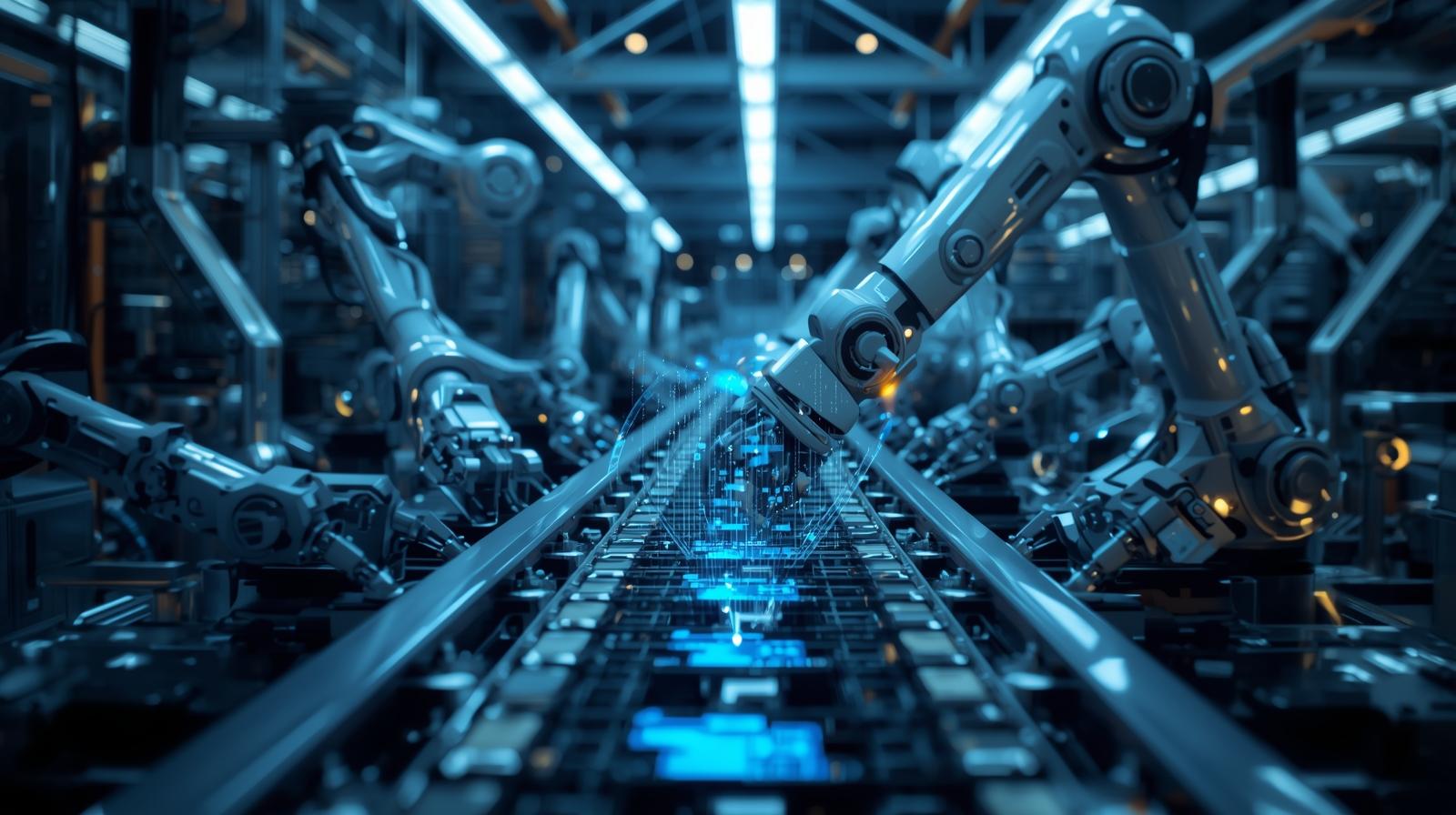

For decades, manufacturing was driven by manual control and mechanical automation. But as production became more complex, the need for smarter systems grew. That’s where machine learning stepped in—a branch of artificial intelligence that enables computers to analyze massive amounts of data, identify patterns, and make predictions without human intervention.

Today, machine learning in manufacturing helps factories reduce waste, improve precision, and boost output. Think of it as giving machines the ability to “think,” anticipate issues, and continuously optimize their performance.

The combination of sensors, IoT devices, and advanced analytics allows machine learning algorithms to process real-time data from every corner of a facility. The result? Smarter decisions, fewer errors, and a dramatic increase in operational efficiency.

Predictive Maintenance: Preventing Downtime Before It Happens

One of the most powerful applications of machine learning in manufacturing is predictive maintenance. Instead of waiting for equipment to fail, machine learning models analyze data from machines to predict when a breakdown might occur. This means maintenance teams can act before a problem disrupts production.

Imagine a factory floor filled with machines equipped with sensors tracking vibration, temperature, and pressure. These sensors constantly feed data into a machine learning system, which then identifies subtle changes indicating potential issues. Rather than reacting to a costly breakdown, the system alerts operators early—saving time, money, and frustration.

Predictive maintenance not only prevents unexpected downtime but also extends the lifespan of machinery. It’s a proactive approach that transforms maintenance from a guessing game into a science-driven process.

Quality Control Enhanced by Machine Learning

Quality control is another area where machine learning shines. Traditional inspections rely heavily on human judgment, which can be inconsistent. But machine learning brings precision and consistency to the process.

Using computer vision and pattern recognition, machine learning systems can detect even the tiniest defects that human eyes might miss. Whether it’s identifying a flaw in a car part, spotting a misaligned circuit, or checking the finish on a product, these systems learn from each inspection and continuously improve their accuracy.

This approach ensures higher product quality, fewer returns, and greater customer satisfaction. By combining machine learning with high-resolution imaging, manufacturers can achieve real-time defect detection, reducing waste and enhancing brand reputation.

Optimizing Supply Chains with Data Intelligence

Manufacturing isn’t just about making things—it’s also about managing complex supply chains. Machine learning helps by analyzing data from suppliers, distributors, and market trends to predict demand and manage inventory more efficiently.

Through predictive analytics, manufacturers can forecast demand spikes, optimize raw material orders, and prevent costly overstocking or shortages. This leads to smoother operations and improved profitability.

For example, a machine learning algorithm might notice that certain raw materials are in higher demand during specific seasons. It then adjusts procurement schedules automatically, ensuring production never slows down due to lack of resources. It’s like having a data-driven crystal ball guiding every decision.

Smart Factories: The Foundation of Industry 4.0

The concept of Industry 4.0—where automation, data exchange, and smart technology converge—is made possible by machine learning. Smart factories are designed to be adaptive, connected, and self-optimizing. They rely on real-time data and algorithms that continuously learn from operations to enhance performance.

In a smart factory, everything is interconnected. Machines communicate with each other, production schedules adjust dynamically, and quality issues are resolved automatically. Machine learning acts as the “brain” behind these systems, turning raw data into actionable insights.

This digital transformation not only increases productivity but also empowers human workers. By automating repetitive tasks, employees can focus on innovation, problem-solving, and strategic improvements.

Reducing Energy Use and Waste

Sustainability has become a core goal in modern manufacturing, and machine learning plays a pivotal role in achieving it. By analyzing patterns in energy consumption and resource use, algorithms can identify inefficiencies and recommend ways to reduce waste.

For instance, a machine learning system might detect that certain machines consume more energy during specific times of day. It can then suggest scheduling adjustments or maintenance to improve efficiency. This not only lowers costs but also supports a greener, more sustainable manufacturing process.

Over time, these intelligent systems can even simulate production scenarios to determine the most energy-efficient configurations, helping manufacturers meet both economic and environmental goals.

Customization and Demand Forecasting

In an era of personalization, customers expect tailored products delivered quickly. Machine learning in manufacturing makes mass customization possible. By analyzing customer data and preferences, manufacturers can predict trends and adapt production accordingly.

This level of flexibility was once impossible with traditional systems. But now, data-driven insights allow companies to produce smaller, customized batches without sacrificing efficiency. It’s the perfect blend of personalization and scalability.

Additionally, demand forecasting powered by machine learning ensures that manufacturers align production with real market needs—reducing waste, optimizing inventory, and improving delivery timelines.

Enhancing Worker Safety Through Intelligent Monitoring

Safety is paramount on the factory floor. Machine learning contributes by monitoring environmental conditions and worker behavior in real time. Through sensors and video analytics, it can detect unsafe situations before accidents occur.

For example, algorithms can identify when a worker enters a restricted area or when machinery operates outside safe parameters. Automatic alerts can then be sent to supervisors, preventing potential injuries. This proactive safety monitoring transforms workplace safety from reactive to predictive.

As machine learning continues to evolve, it’s expected that smart wearables and real-time hazard detection systems will become standard in manufacturing environments.

Overcoming Implementation Challenges

While the benefits are clear, integrating machine learning into manufacturing isn’t without challenges. Companies often face issues like data quality, system integration, and workforce training. Machine learning models need accurate, consistent data to function effectively, and that requires investment in sensors, connectivity, and infrastructure.

Another challenge lies in bridging the skills gap. Many traditional manufacturers must train employees to work alongside AI-driven systems. However, those who embrace the change often find that the combination of human expertise and machine intelligence leads to exceptional results.

Successful implementation depends on strategy. Start small—focus on one process, test results, and scale gradually. Over time, the data gathered from these smaller projects can power broader transformation across the organization.

The Future of Machine Learning in Manufacturing

The future of machine learning in manufacturing is bright, promising a world where factories are fully autonomous, adaptive, and data-driven. As algorithms become more sophisticated, they’ll enable real-time decision-making, greater efficiency, and continuous improvement.

Emerging technologies such as digital twins—virtual replicas of physical systems—will allow manufacturers to test and optimize production before making real-world changes. Combined with machine learning, this approach will eliminate guesswork and maximize performance.

In the years ahead, we’ll see even tighter integration between AI, robotics, and machine learning, creating manufacturing ecosystems that are smarter, safer, and more responsive than ever before.

Conclusion

Machine learning in manufacturing represents more than just technological progress—it’s a complete reimagining of how industries operate. By harnessing data and intelligent algorithms, factories can predict problems before they occur, ensure higher product quality, optimize energy use, and meet customer demands with unprecedented agility.

The result is a new era of innovation where efficiency, safety, and sustainability go hand in hand. Those who embrace this transformation today are not only improving operations—they’re shaping the future of global manufacturing.

FAQ

1. How is machine learning used in manufacturing?

Machine learning is used to predict maintenance needs, improve quality control, optimize supply chains, and enhance production efficiency through data-driven decision-making.

2. What is predictive maintenance in manufacturing?

Predictive maintenance uses machine learning to analyze equipment data and predict potential failures before they occur, reducing downtime and maintenance costs.

3. How does machine learning improve product quality?

By analyzing visual and performance data, machine learning can detect defects early, maintain consistency, and ensure products meet high-quality standards.

4. What challenges do manufacturers face when adopting machine learning?

Common challenges include poor data quality, integration issues, high initial investment, and the need to train employees on AI-driven systems.

5. What is the future of machine learning in manufacturing?

The future involves autonomous factories, advanced robotics, and digital twins powered by machine learning, leading to smarter, safer, and more efficient production systems.