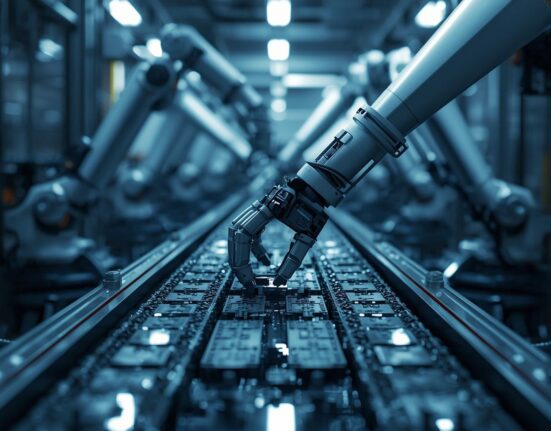

In today’s rapidly evolving industrial landscape, robots are no longer confined to high-tech labs or automotive assembly lines. They’re everywhere—from logistics and manufacturing to healthcare and agriculture. Yet as automation becomes more sophisticated, companies face a new challenge: ensuring their human workforce keeps pace. That’s where robotics workforce training solutions come into play.

Let’s dive into the world of top vendors leading the charge in helping workers and organizations transition smoothly into this automation-driven future.

The Rising Demand for Robotics Workforce Training

Automation is accelerating, but people remain at the heart of every successful transformation. While robots handle repetitive or dangerous tasks, humans are needed to program, maintain, and optimize them. However, the skills gap is widening.

According to industry reports, millions of workers will need reskilling in robotics and automation over the next decade. This isn’t just about keeping jobs—it’s about staying relevant. Transition words like “therefore” and “as a result” highlight that companies investing in training today are safeguarding their competitive edge tomorrow.

Effective robotics workforce training doesn’t just teach how to operate a robot. It fosters critical thinking, problem-solving, and adaptability—skills that allow employees to work alongside intelligent machines rather than be replaced by them.

Key Elements of a Successful Robotics Training Program

Before we explore the top vendors, it’s worth understanding what makes a strong robotics workforce training solution.

A great program usually includes:

- Hands-on practice with real robots: Learners engage directly with robotic arms, drones, or autonomous systems.

- Simulation and virtual labs: Digital environments allow trainees to practice safely and repeat exercises without hardware constraints.

- Curriculum integration: The best solutions blend theory, programming, maintenance, and safety.

- Certification pathways: Recognized credentials validate employees’ new competencies.

- Scalable delivery: Online and hybrid learning ensures accessibility for global teams.

When these elements combine, the result is a confident, capable workforce ready for the future of automation.

Top Vendors Leading the Robotics Workforce Training Revolution

Now, let’s look at the top vendors offering robotics workforce training solutions that help industries close the skills gap and prepare their teams for next-generation automation.

1. FANUC America

FANUC has become synonymous with industrial robotics. Its training programs are structured to serve both beginners and advanced technicians. The FANUC Certified Education Training (CERT) program equips students with hands-on experience in operating and programming FANUC robots.

Courses cover programming, troubleshooting, and integration. Many universities and technical colleges partner with FANUC to integrate its materials into STEM curriculums. The focus on practical skills ensures that participants can directly apply what they learn to real manufacturing environments.

2. ABB Robotics

ABB’s Robotics Training Services are recognized worldwide for their comprehensiveness. ABB combines classroom instruction with virtual reality simulations and hands-on labs.

Its RobotStudio® software provides a virtual environment where users can simulate robot operations, reducing downtime and improving training efficiency. Furthermore, ABB offers customized corporate programs, ensuring companies can tailor learning modules to specific production lines or automation setups.

By blending digital and physical learning, ABB empowers workers to stay proficient in both emerging and traditional automation technologies.

3. Universal Robots (UR Academy)

Universal Robots revolutionized collaborative robots (cobots) by making automation accessible to small and mid-sized businesses. Its UR Academy is an industry leader in user-friendly, modular training.

Through free online courses, video tutorials, and in-person workshops, UR helps employees quickly grasp robot setup, safety, and application deployment. The platform’s emphasis on intuitive learning ensures even non-technical staff can master cobot operations within hours.

UR’s global learning ecosystem also includes partner-led training centers, enabling continuous workforce development across industries.

4. Siemens Learning Advantage

Siemens’ Learning Advantage platform provides a full spectrum of automation and robotics training. Its strength lies in the integration of robotics within industrial control systems and smart manufacturing.

Trainees can access personalized learning paths covering automation design, robotics programming, and system optimization. Siemens also leverages digital twin technology, allowing workers to test and refine production workflows virtually before implementing them in the real world.

This combination of theory, simulation, and practice ensures long-term retention and practical understanding.

5. Yaskawa Motoman Training Services

Yaskawa’s training services stand out for their precision and real-world relevance. The company offers hands-on instruction through certified centers across North America and Asia.

Programs such as Basic Programming with YRC1000 and Advanced Maintenance Techniques give technicians the skills to keep robotic systems running efficiently. Yaskawa also integrates safety certification into its training modules, ensuring compliance with global safety standards.

Its focus on maintenance and technical support makes it an essential choice for organizations operating high-volume robotic systems.

6. Rockwell Automation (Automation University)

Rockwell Automation is a global powerhouse in industrial training. Its Automation University offers both instructor-led and e-learning options focusing on robotics integration within manufacturing ecosystems.

Courses cover programmable logic controllers (PLCs), industrial networks, and robotics communication protocols. Additionally, Rockwell’s partnerships with academic institutions expand access to learners worldwide.

As more manufacturers adopt digital transformation, Rockwell’s training ensures engineers and operators stay competent with the latest tools and standards.

7. NVIDIA Deep Learning Institute (DLI)

While not a traditional robotics vendor, NVIDIA’s Deep Learning Institute plays a crucial role in modern robotics education. With AI powering perception and decision-making in autonomous robots, NVIDIA provides courses that bridge robotics and machine learning.

Participants learn how to train neural networks, deploy edge AI models, and integrate computer vision into robotics applications. This training is invaluable for developers and engineers working on next-generation intelligent robots.

NVIDIA’s influence underscores how robotics workforce training increasingly overlaps with artificial intelligence education.

8. MIT xPRO Robotics Programs

MIT xPRO offers professional courses in Industrial Robotics and Autonomous Systems, catering to engineers and managers alike. These programs combine academic rigor with practical relevance.

Participants explore system integration, robotic kinematics, and automation design, often through case studies and simulation projects. MIT’s partnership with global employers ensures that graduates gain in-demand, industry-recognized skills.

With flexible online formats, these programs make world-class robotics education accessible to professionals worldwide.

9. KUKA College

KUKA College provides an international network of training centers specializing in robotics programming and maintenance.

Their programs emphasize practical exercises using real industrial robots, ensuring learners gain confidence in both basic and advanced control systems. KUKA’s structured certification path—from beginner to expert—encourages lifelong learning.

By focusing on safety, efficiency, and precision, KUKA College helps organizations maintain high productivity standards in automation environments.

10. Coursera and edX Robotics Courses

Finally, no discussion of top vendors would be complete without mentioning online education platforms like Coursera and edX.

They collaborate with universities and industry leaders (including Google, Stanford, and the University of Pennsylvania) to deliver robotics and automation courses globally. From Python programming for robotics to machine vision systems, learners can tailor their education to specific career goals.

These platforms democratize robotics training, making it possible for anyone—from technicians to executives—to gain future-ready skills at their own pace.

Why Investing in Robotics Workforce Training Matters

The impact of investing in robotics workforce training goes far beyond productivity. Companies that equip their teams with robotics expertise also improve retention, morale, and innovation.

When employees see growth opportunities, they’re more motivated to embrace automation rather than fear it. Moreover, upskilled workers can identify creative uses for robotics that drive efficiency and safety improvements across departments.

In short, robotics training isn’t an expense—it’s an investment in people and progress.

How to Choose the Right Robotics Training Vendor

Selecting a training provider can be daunting, but a few considerations can simplify the process:

- Assess your goals: Do you need programming, maintenance, or operations training?

- Check vendor credentials: Choose certified or accredited institutions.

- Prioritize flexibility: Look for options that combine online and in-person learning.

- Seek ongoing support: The best vendors offer post-training mentorship or refresher courses.

- Match technology with your systems: Ensure the training aligns with your equipment or software ecosystem.

The right vendor will not only build technical competence but also cultivate a culture of continuous improvement.

The Future of Robotics Workforce Education

Looking ahead, robotics training will become even more immersive and personalized. Augmented reality (AR), virtual labs, and AI-driven learning analytics will tailor lessons to individual skill levels.

As industries adopt collaborative robots and smart systems, learning will shift from one-time certifications to continuous development. Employees will upskill dynamically, just as technology evolves.

The future belongs to organizations that treat learning as an ongoing journey—not a destination.

Conclusion

Robotics workforce training solutions are the cornerstone of modern industrial success. The top vendors—FANUC, ABB, Universal Robots, Siemens, and others—are not just teaching programming; they’re preparing humans to thrive in partnership with machines.

Whether through virtual simulation, hands-on practice, or AI-enhanced education, the goal remains the same: to build a confident, capable workforce ready for a smarter, more automated world.

Investing in robotics workforce training today ensures your company stays ahead tomorrow—where people and robots work together seamlessly.

FAQ

1. What is robotics workforce training?

Robotics workforce training involves teaching employees how to operate, program, and maintain robotic systems safely and efficiently.

2. Why is robotics training important for businesses?

It helps companies close the skills gap, boost productivity, and ensure employees can adapt to automation technologies effectively.

3. Which industries benefit most from robotics training?

Manufacturing, logistics, healthcare, and agriculture see the greatest benefits, but nearly all sectors are now exploring robotics applications.

4. How long does it take to complete robotics workforce training?

Program lengths vary—from a few days for basic operation to several months for advanced programming or certification.

5. What are the main factors to consider when choosing a training vendor?

Look for vendors with certified instructors, flexible formats, industry partnerships, and training that matches your equipment and goals.