Introduction: Why ROI Matters in Robotics Upskilling

Robotics is reshaping industries, but the machines themselves are only part of the equation. The real question leaders face is: how do we measure the value of investing in people? Calculating the ROI of robotics workforce upskilling ensures organizations make smarter decisions while preparing teams for the future.

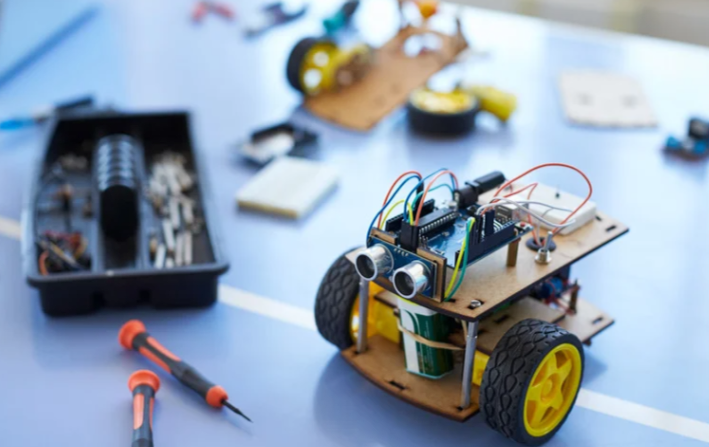

What Is Robotics Workforce Upskilling?

It’s the process of training employees to work effectively with robotic systems — from programming and maintenance to safety and collaboration.

Why Calculate ROI for Upskilling?

Aligning Training with Business Goals

ROI proves that training initiatives connect directly to outcomes.

Securing Leadership Buy-In

Clear numbers help justify investments in training programs.

Driving Continuous Improvement

Tracking ROI shows where programs succeed — and where they need refining.

Building Workforce Confidence

Employees feel valued when training is treated as an investment, not a cost.

Key Factors in ROI of Robotics Workforce Upskilling

Direct Costs

Tuition, course fees, training software, and instructor costs.

Indirect Costs

Time away from regular duties, travel, and administrative support.

Tangible Benefits

Productivity gains, fewer errors, reduced downtime.

Intangible Benefits

Employee morale, reduced turnover, and improved safety culture.

How to Calculate ROI of Upskilling

Step 1: Identify Training Costs

Add up direct and indirect expenses.

Step 2: Measure Productivity Improvements

Track efficiency gains in tasks performed with robotics.

Step 3: Assess Error Reduction

Fewer mistakes mean cost savings and improved quality.

Step 4: Consider Workforce Retention

Lower turnover saves recruitment and onboarding costs.

Step 5: Use the ROI Formula

ROI=(TotalBenefits−TotalCosts)TotalCosts×100ROI = \frac{(Total Benefits – Total Costs)}{Total Costs} \times 100ROI=TotalCosts(TotalBenefits−TotalCosts)×100

Case Example: ROI in Manufacturing Robotics

A factory invests $50,000 in upskilling. Within one year:

- Productivity rises 20%.

- Downtime drops by 15%.

- Employee turnover decreases by 10%.

Result: $120,000 in measurable benefits, creating an ROI of 140%.

Challenges in Measuring ROI of Upskilling

- Difficulty quantifying intangible benefits like morale.

- Long-term payoffs may not show immediately.

- Training effectiveness can vary across teams.

Best Practices for Maximizing ROI

Align Training with Strategy

Focus on skills that impact core business goals.

Leverage Technology

Use virtual training and simulations to reduce costs.

Encourage Continuous Learning

Ongoing programs ensure skills evolve with robotics.

Measure Regularly

Track progress at set intervals for accurate ROI reporting.

Future Trends in Robotics Workforce Upskilling ROI

AI-Powered Analytics

Smarter tools will measure ROI with real-time data.

Personalized Training Programs

Tailored learning paths maximize value for each employee.

Global Certification Standards

Credentials will make ROI comparisons easier across industries.

Conclusion: Proving the Value of People in Robotics

Calculating the ROI of robotics workforce upskilling isn’t just a financial exercise — it’s a leadership strategy. Companies that invest in people see returns in productivity, safety, and innovation, making their workforce as future-ready as the robots they use.

FAQ

1. What is robotics workforce upskilling?

It’s training employees to work confidently with robotic systems and automation.

2. Why should ROI be measured in upskilling?

To justify investment, align training with goals, and track results.

3. How do you calculate ROI for training?

Compare total benefits against total costs using the ROI formula.

4. What benefits come from upskilling workers in robotics?

Higher productivity, fewer errors, lower turnover, and better safety.

5. What challenges exist in calculating ROI?

Measuring intangible benefits and capturing long-term results are the biggest hurdles.